Plenty of people can cut glass.

Bend it? That’s a different story.

We bend glass for lamp panels (sometimes called slag glass pamp panels) and also for window sash, china cabinet doors, display cases, clock faces, picture frames and so on.

You can trust Curran Glass Studio to create replacement pieces for your most precious glass lampshades. Our extensive inventory of colored glass, much of it from the early 20th century and no longer made, means that we can match glass in antique fixtures. Some shades have frosted panels or reverse painting; we offer those services as well.

We DO NOT provide bent tempered glass, but will gladly provide a referral for it, or for a project too large for any of our kilns.

We’ve bent literally thousands of panels for the repair of antique slag glass (bent glass) lamps. Whether your lamp has one broken piece or no glass left at all, we can usually help you. We prefer to have one good original piece to work with so we can match the bend and glass color, but will work from the lampshade itself if necessary. We ship bent glass from coast to coast.

Bent Lamp Panels

How To Order Bent Glass From Curran Glass

For bent glass orders, first read “Bent Glass Lamp Panel Ordering Information” below, including the tips in Item 5. Then download and complete the Order Form in Item 4. Please include a copy of this form with anything you send to us. If you don’t have a printer, you can submit the information online.

If you do this, please make sure to include your name, address, phone number, and email address inside the box with any items you send us.

Prices

These prices are for lamp panels only, not for furniture bends or hanging light fixtures. Please ask for a quote.

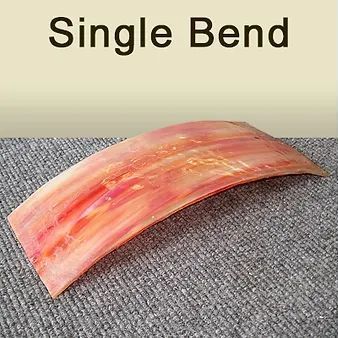

SINGLE BEND--1st panel

$85 (Additional panels $65 each)

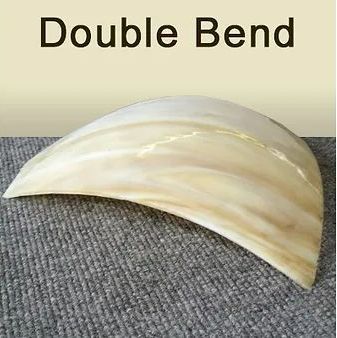

DOUBLE BEND--1st panel

$100 (Additional panels $85 each)

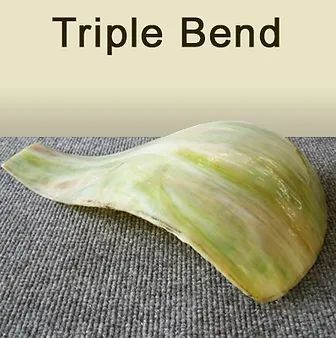

TRIPLE BEND--1st panel

$150 (Additional panels $125 each)

These prices include the cost of ordinary glass used in fabricating the new panel(s). Specialty glass will require additional charges.

Pieces that require special work—such as painted or acid-etched pieces, beveled edges, wheel-engraved pieces, severe protrusions, extreme angle bends, or especially large panels—will be individually quoted.

To guarantee duplication of bends, we need you to supply one good sample panel.

Return shipping charges will be added to these prices, so please do not send a check with your order.

Avoid sending an entire lampshade. If you must do this, it creates a lot of extra work at our end, and there will be an additional charge of up to $50.

Return shipping costs are at customer’s expense and can’t be calculated until your job is complete, so please wait to pay until we let you know the full amount due.

Orders under $100 will be subject to a $15 boxing charge.

Flat panels with no bend are available. Please email or call to ask about cost.

China and curio cabinet bends (including serpentine bends), custom sash bends and crown glass are also available. Please send your specifications for a price quote.

Prices subject to change.

Ordering Information

1. Send a good, clean sample.

2. Label clearly.

3. Package well. Please do not use clear packing tape on bubble wrap.

5. Read the following tips for more details.

Curran Glass Studio has been bending lamp panels for over 50 years. The following tips will help you get the best possible duplicate panels, with a good match in both color and size.

Send a good panel for us to work from.

To create a good duplicate, we need a good original to work from. Try to send one that is original to the fixture and representative in color and texture.

Clean the panel well and label it on the back with your name and how many you need. If your panel is reverse painted, don’t put tape or labels on the paint--adhesive can pull it off.

We will do our best to match your panel in color, texture, size and shape. We inventory over 3,000 molds and over 4,000 sheets of colored opalescent glass in nearly every texture and density. If your panel is unusual glass, and you have some, send the glass along. If not, we’ll do the best we can.

Sometimes bent panels--mostly from table lamps--will crack, run, or split after they’re removed from their metal frames. We believe the use of too many high-wattage light bulbs causes stress in the panel. Once the panel is removed from the lamp and the weight displacement changes, the panel cracks in a way very similar to a heat crack.

If a panel cracks this way while in our possession, we will re-make it at our expense. If a panel cracks this way during shipment, you could file a claim for breakage with your shipper, but we don’t advise it because the problem was probably inherent in the glass prior to shipment. We do advise filing claims if the box your panel was shipped in shows signs of abuse and the glass was clearly shattered. If you take good care in packaging your panels for shipment, we rarely experience any problems with breakage.

There are two common ways to insert glass panels in light fixtures. One is with clips that fold down over the glass. The other involves a brass U-channel that wraps around each panel and is soldered into place.

Although you can often re-use the existing brass U-channel, it is better to re-wrap the new panel with a new piece of brass. But most of the brass available for this purpose is too stiff for you to wrap it around a complex bend, so we recommend annealing the brass to soften it first. To do this, heat the brass with a propane torch until it is red-hot. Let the brass cool naturally until it is room temperature.

If the duplicate panel you receive from us is a bit too large, either wet-sand or wet-grind the glass to size. You can also groze the panels down, but it’s safer to grind them. Before we ship the new panels to you, we do our best to grind them down on a 120-grit diamond grinding wheel that is cooled with a steady stream of water.

If you find that you need more panels than you ordered, please re-order within 2 weeks of receiving your first order. We keep patterns and molds set aside for a couple of weeks before “filing” them.

Bent Glass Order Form

Fill out the form provided, or download the form below and fill it out.